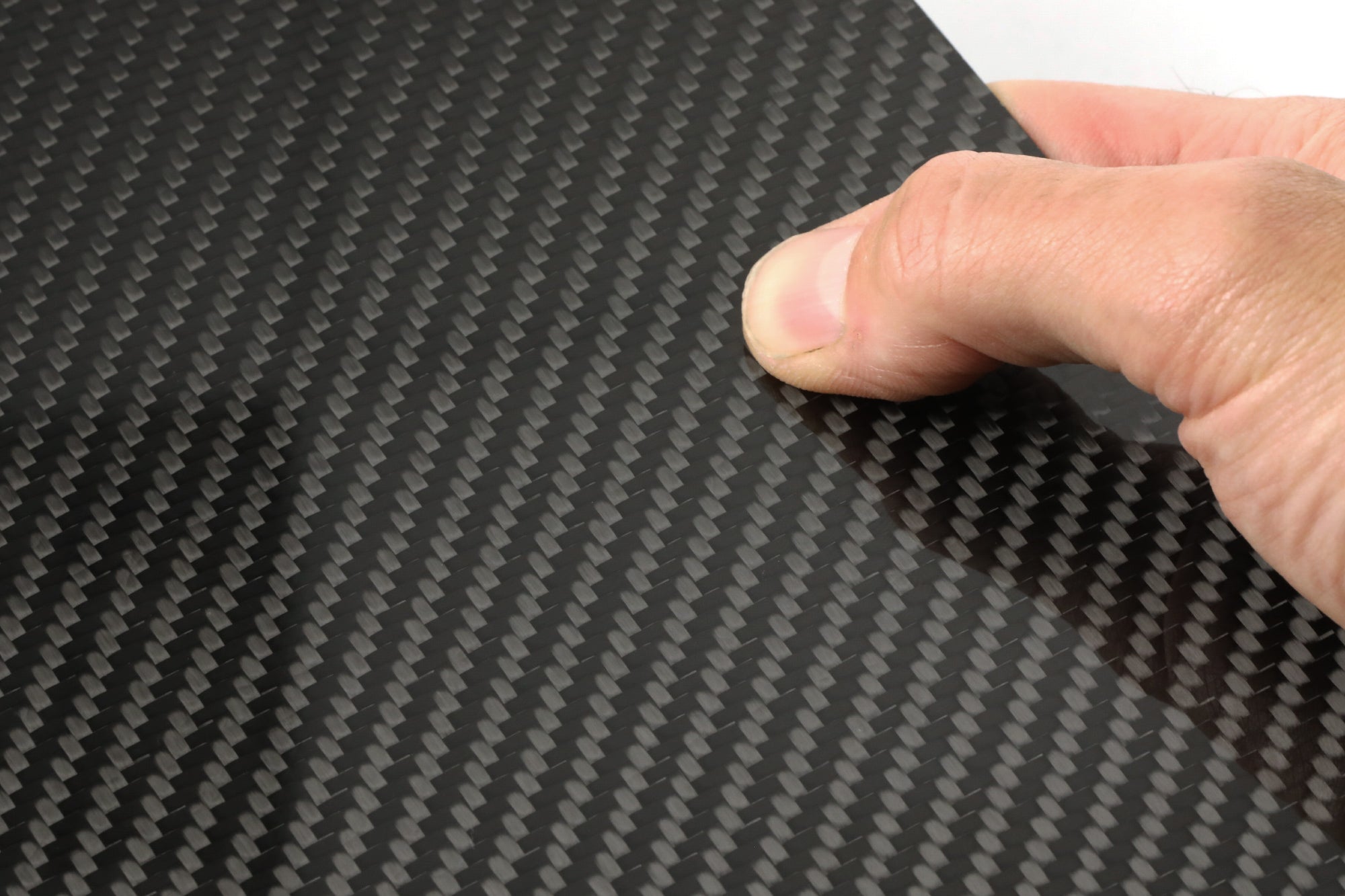

Real Carbon Fiber 3k twill Sheets (Glossy Finish)

- click on add to cart

- Click on checkout

- Fill in information

- click on Complete order

ordering through the website will allow us to processes your order faster and thus faster delivery.

- order today and receive within 2-3 working days in beirut and 3-4 working days out of beirut.

- Cash on delivery

- Delivery all over Lebanon

- delivery will contact you ahead of time before delivery

Overview

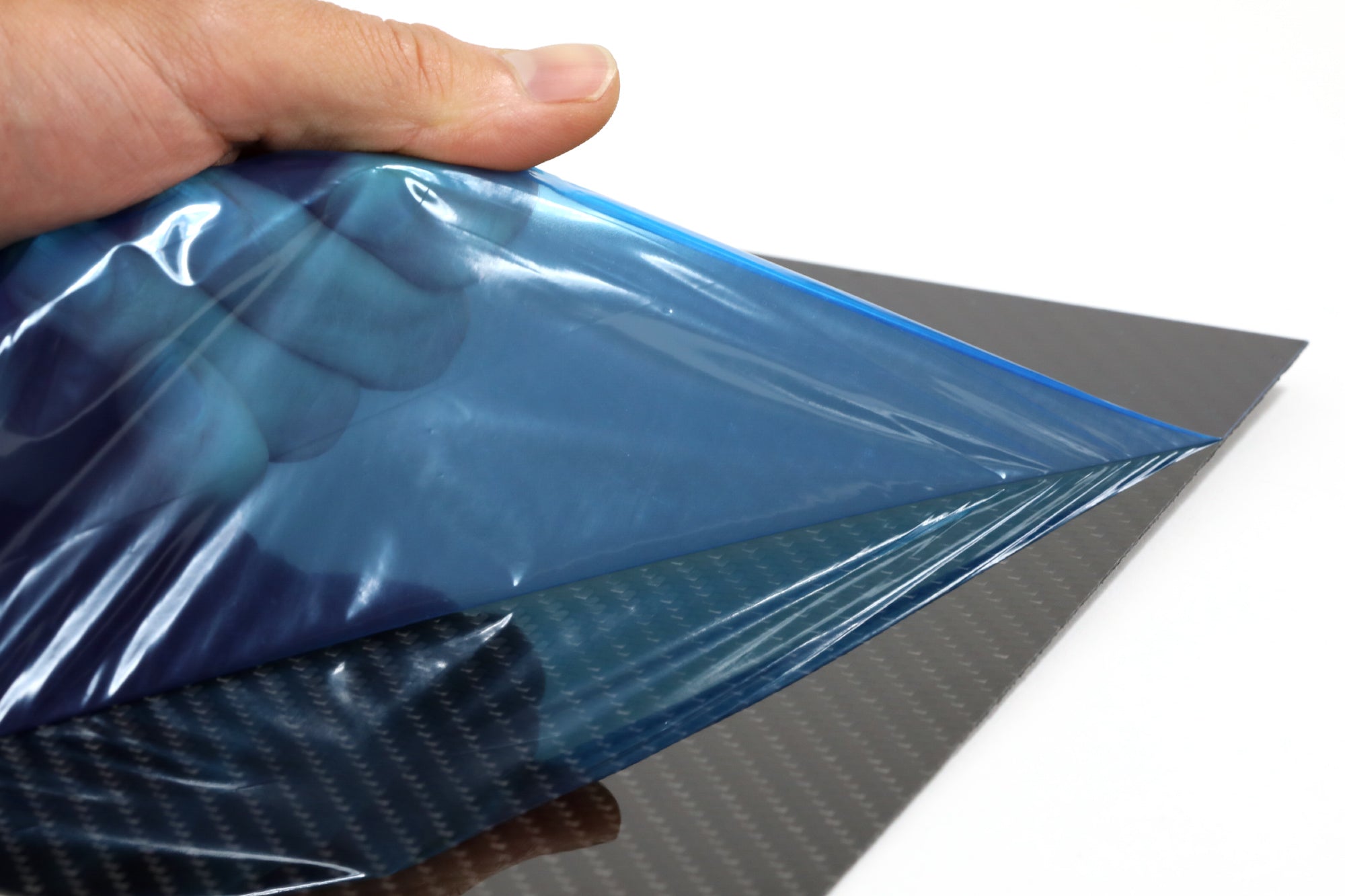

The same performance carbon fiber used in Carbonize premium accessories is now available as raw material. Carbonize 3K Twill Sheets are manufactured from 100% aerospace-grade carbon fiber and high-performance epoxy resin, engineered for maximum strength-to-weight efficiency and a deep gloss technical finish.

Designed for builders who demand structural performance and a precision woven aesthetic.

Technical Features

Material System

100% genuine 3K carbon fiber reinforcement with structural epoxy matrix. No fiberglass, no plastic fillers.

Weave Architecture

2×2 twill weave using 3K carbon tows, balancing strength, flexibility, and uniform load distribution.

Tensile Strength

Up to 3,500–3,800 MPa fiber strength, supporting high load-bearing applications.

Elastic Modulus

Approximately 220–240 GPa, delivering exceptional rigidity under stress.

Density

~1.6 g/cm³, providing extreme strength at minimal weight.

Surface Finish

High-definition gloss twill finish for a premium composite appearance.

Thermal Tolerance

Operational temperature range of -50°C to 250°C, with short-term resistance up to 250°C.

Corrosion Resistance

Immune to rust and highly resistant to chemicals, moisture, and UV degradation.

Applications

Lightweight structural parts, automotive components, enclosures, panels, robotics, custom fabrication.

Why Carbonize Sheets

Carbonize sheets use the same real carbon fiber trusted in our finished products. Each panel is produced under controlled pressure and curing cycles to ensure consistent fiber density, structural reliability, and professional-grade surface quality.